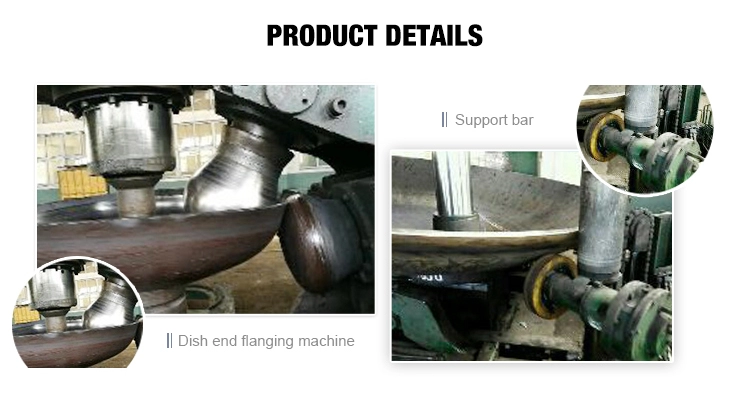

hydraulic 6 meters head dished end spinning flanging machine for sale

The hydraulic dish end forming and flanging machine is specialized equipment used to manufacture various types of dished heads, including elliptical, torispherical, hemispherical, flat, taper, and spherical heads. By adopting advanced spinning and hydraulic pressing processes, the machine ensures high precision, stable forming quality, and superior efficiency for medium and large-scale head production.

What Is a Dish End Machine?

A complete dish end production line typically consists of:

- Dished Head Forming Machine – for initial shaping by spinning or hydraulic pressing.

- Flanging Machine – for edge flanging of the formed head.

- Edge Trimming Machine – for fine edge finishing and dimensional accuracy.

With adjustable spinning speed, automatic hydraulic control, and strengthened frame structure, the machine supports high-volume industrial manufacturing with stable results.

Machine Control System

The dish end machine features an independent hydraulic, power, and electrical control system with centralized button operation. Emergency stop switches are installed for operational safety. Jogging and semi-automatic modes enable flexible working, while automatic return is available based on product requirements. Both fixed pressing and constant pressure forming are selectable.

Electrical System Overview

- PLC-based electronic control system for precision automation.

- PLC & relays from Omron Japan; other components from globally recognized brands.

- Primary circuit voltage: 380V / 220V, control voltage: 24V.

- Equipped with rectifier + filtering system for stable and safe operation.

- High sensitivity, long service life, and strong reliability.

Available Power Supply: 380V/50Hz/3PH, 220V/60Hz/3PH

Product Images

Applications

This dish end spinning & flanging machine is widely used across multiple industries:

- Pressure vessel and boiler manufacturing

- Chemical, petrochemical, and refinery equipment production

- Food processing tanks and stainless steel containers

- Pharmaceutical and sanitary tank fabrication

- Oil, gas, LNG, cryogenic vessel production

- Water storage, air compressor tanks, and fire-fighting tanks

- Brewing, wine, beverage and storage industries

- Shipbuilding and hydraulic engineering

Packing & Shipping

- All equipment surfaces treated with anti-rust oil before shipping.

- Electrical components and accessories packed in wooden crates.

- Main machine fixed with reinforced steel frames or pallets for sea transport.

- Door-to-door delivery available (EXW, FOB, CFR, CIF, DDP).

Full export documentation support: invoice, packing list, CO, Form E, embassy certification, etc.

After-Sales Service

- 12-month warranty on core components.

- Lifetime technical support with remote diagnostics.

- Engineers available for overseas installation & training.

- Spare parts available worldwide.

- 24/7 support via WhatsApp and email.

Company Profile

Dalian Jiuying Machinery Equipment Co., Ltd., founded in 2012, specializes in manufacturing dish end machinery, head forming equipment, and automatic tank production solutions. With a strong engineering team and advanced machining capability, our products are widely exported to:

USA, Italy, Russia, Vietnam, Mongolia, Georgia, Turkey, India, UAE, Algeria, Philippines, Indonesia, Malaysia, Bangladesh, South Africa, Germany, Slovakia, Sri Lanka, and more.

We focus on innovation, stable performance, and customer satisfaction, aiming to be a leading solution provider in automatic forming and welding machinery.

Contact Us

Phone/WhatsApp: +86-13322202758

Fax: 0411-39015062

Email: liu@weldcnc.com